Honeycomb

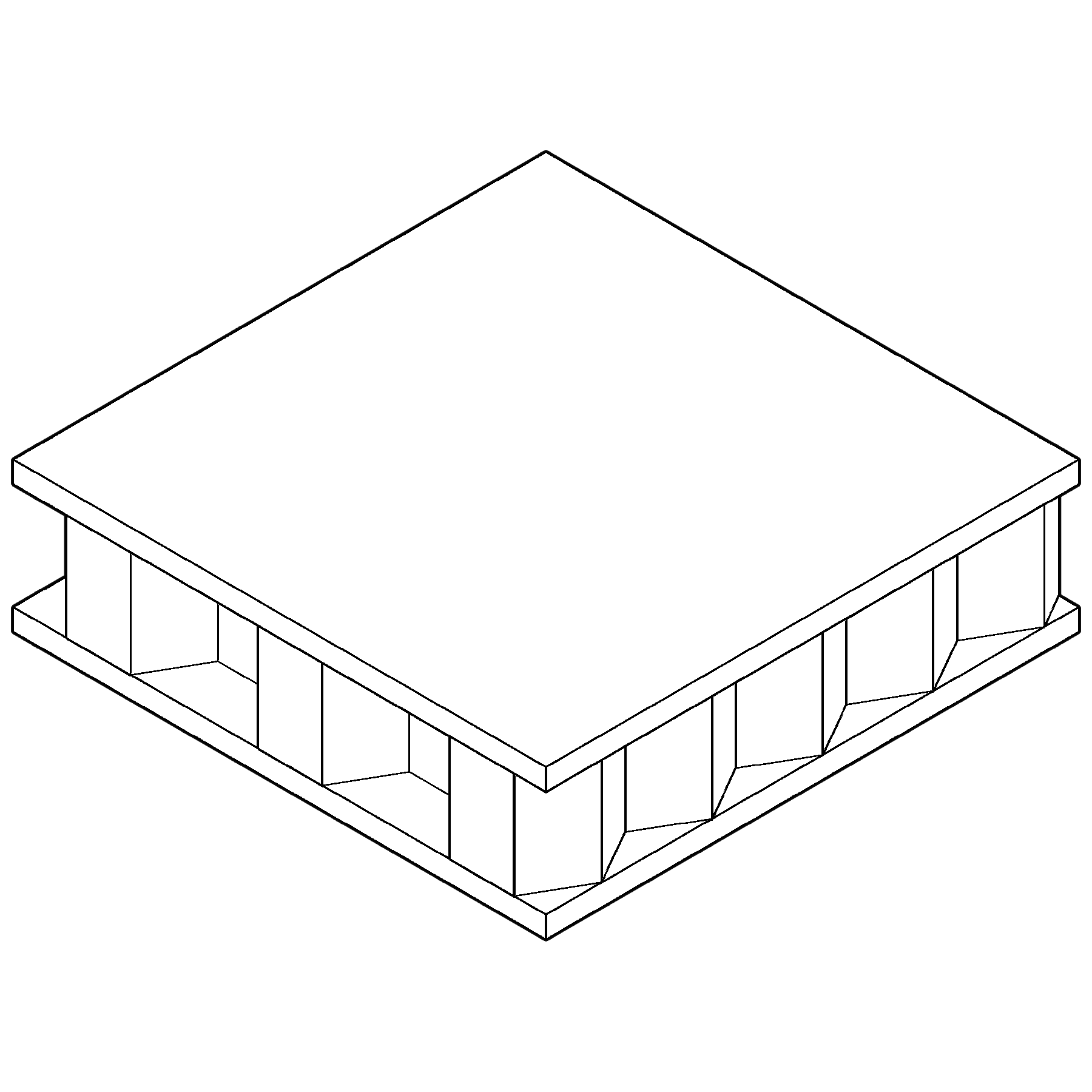

Honeycomb sandwich structured consist two main elements. Honeycomb core and face material, combing this together with the help of adhesive form Honeycomb Sandwich panel. Honeycomb structure is known for its excellent strength, rigidity and light weight.

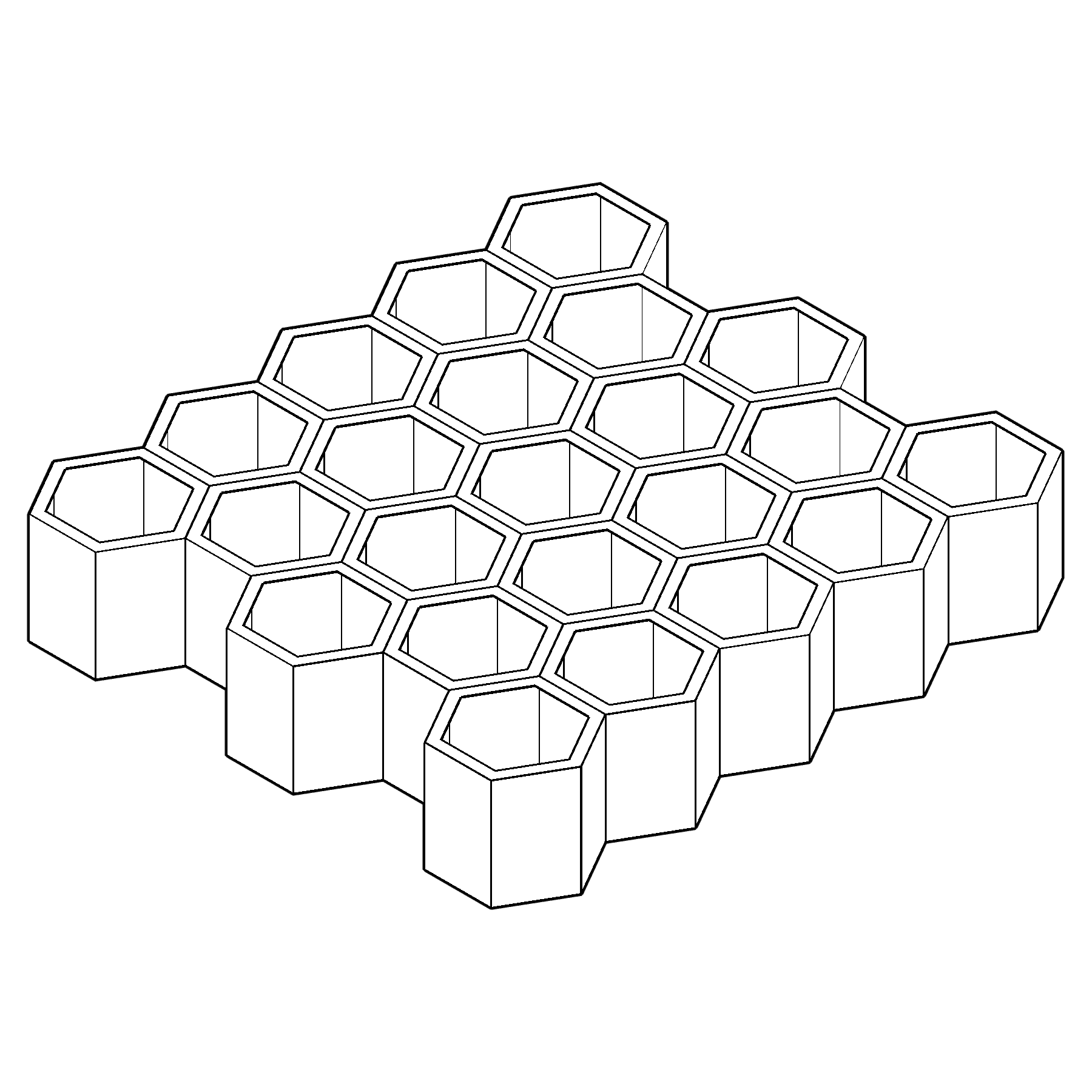

The Honeycomb core material consists hexagonal cells which align horizontally to form a sheet, strength of honeycomb core varies with the size of hexagonal cells, the small size has excellent strength compared to large cell size, honeycomb core is manufactured using different material such as paper, metal and plastic

Honeycomb structures are composite material includes sandwich-structured composite with honeycomb cores. Honeycomb structures are manufactured by using a variety of different materials, depending on the intended application and required characteristics. Paper, fibreboard and plastics, used for low strength and stiffness for low load applications, Aluminium, Fiber reinforced plastics and metal used for high strength and stiffness for high performance applications. The strength of sandwich panels depends on the size of the panel, facing material used and the number or density of the honeycomb cells within it. Honeycomb composites are used widely in many industries, from aerospace industries, automotive and furniture to packaging and logistics.

Paper Honeycomb

Paper Honeycomb is structural and packing material manufacture using paper honeycomb core and different grammage of face paper. Paper Honeycomb Core is made from layers of paper sheets bonded together by parallel and uniformly spaced lines of adhesive which on an expanding form the hexagonal cell sheet. Paper Honeycomb Panel is a structural material made by layering a paper honeycomb core between two layers of paper sheets, glue with the help of adhesive this form a structure of the paper honeycomb sandwich.

The advantage of combining paper honeycomb core with the surface material make it possible to achieve unique characteristics, Highest strength-to-weight ratio, Highest stiffness-to-weight ratio, Uniform crushing strength under compression, Low impact on environment and Sustainable cost savings.

Paper honeycomb core used as filling material in the doors, furniture, wall partition and as honeycomb sandwich panels. Honeycomb sandwich panels used as energy absorption material, light weight construction panels and for complex packaging solutions.

Honeycomb Process

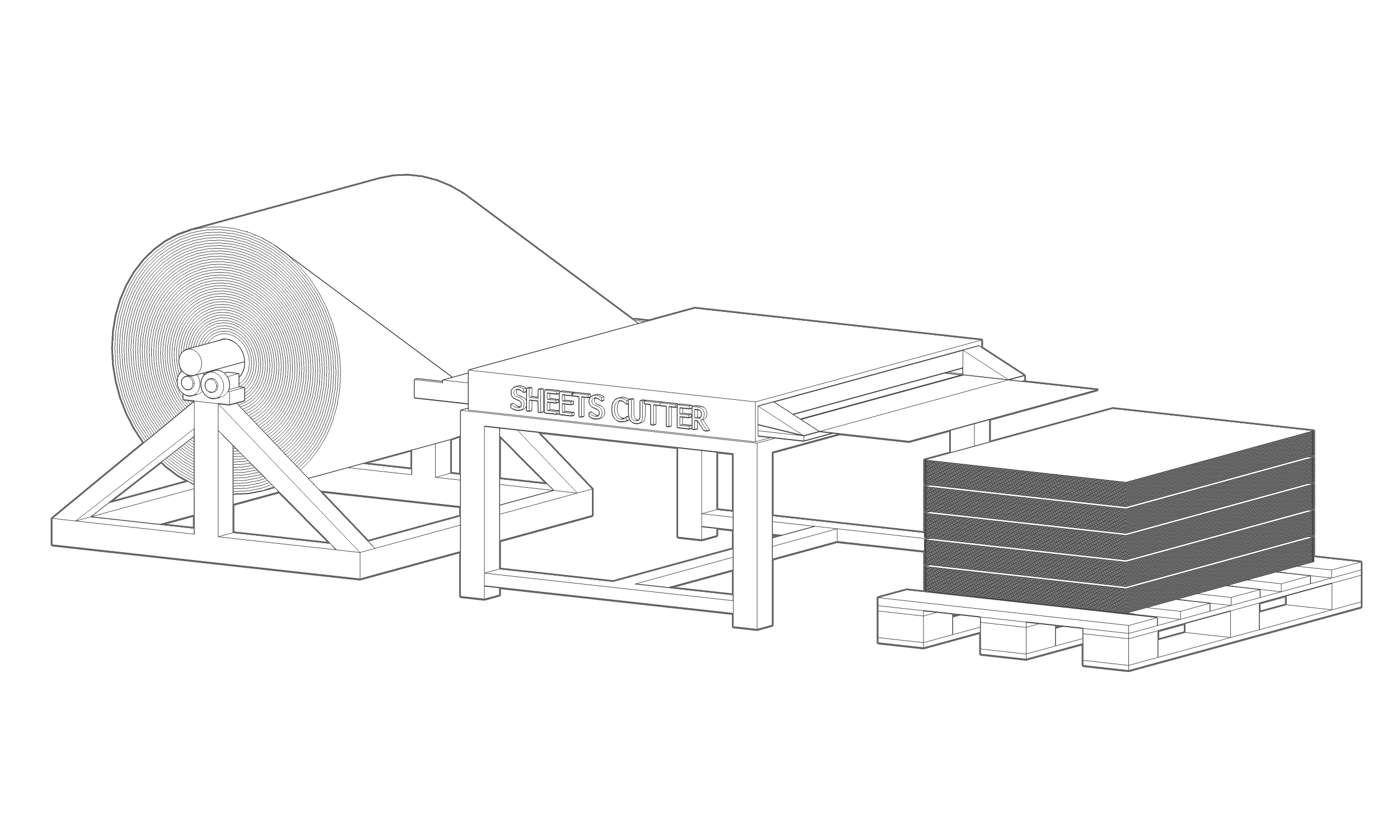

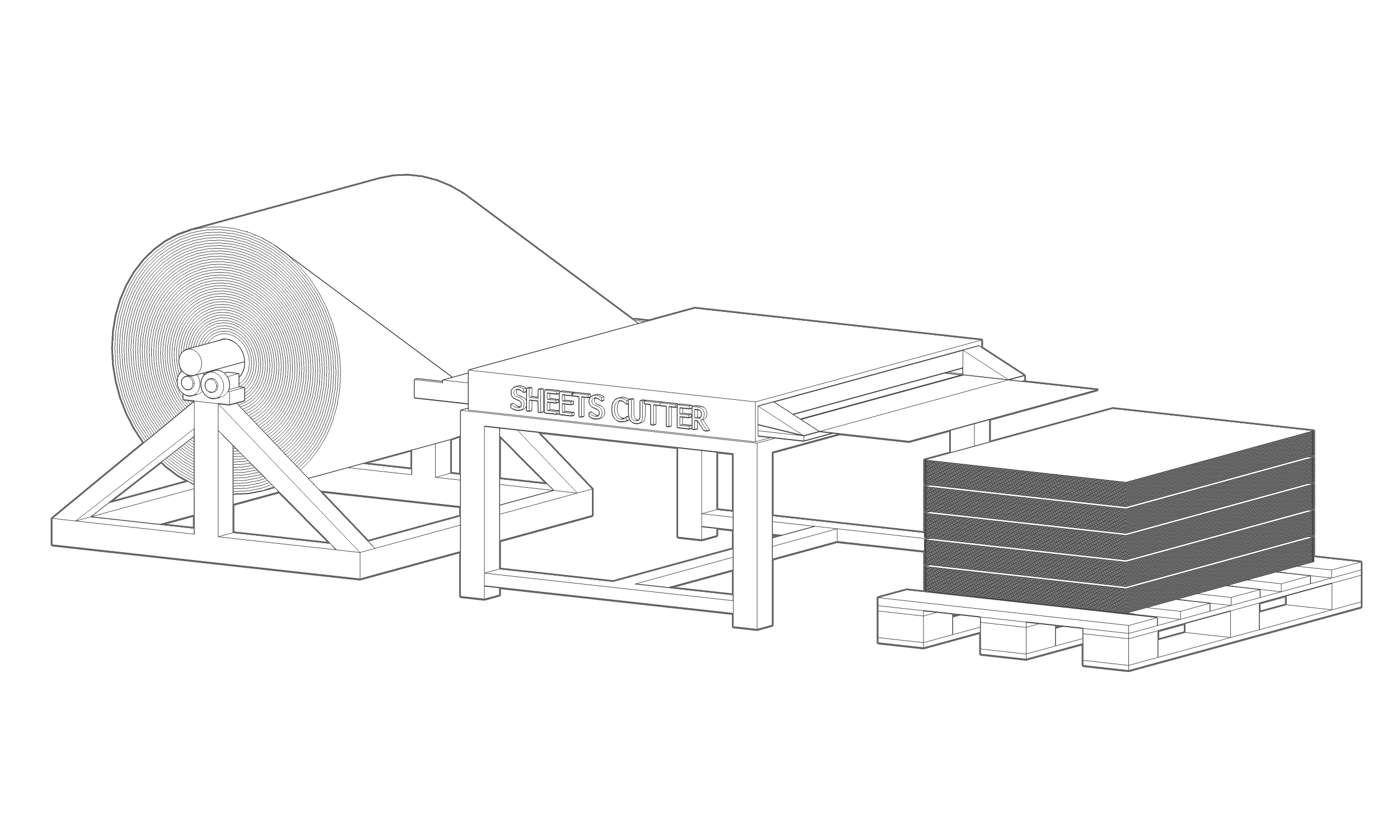

Kraft paper rolls converted to paper sheets

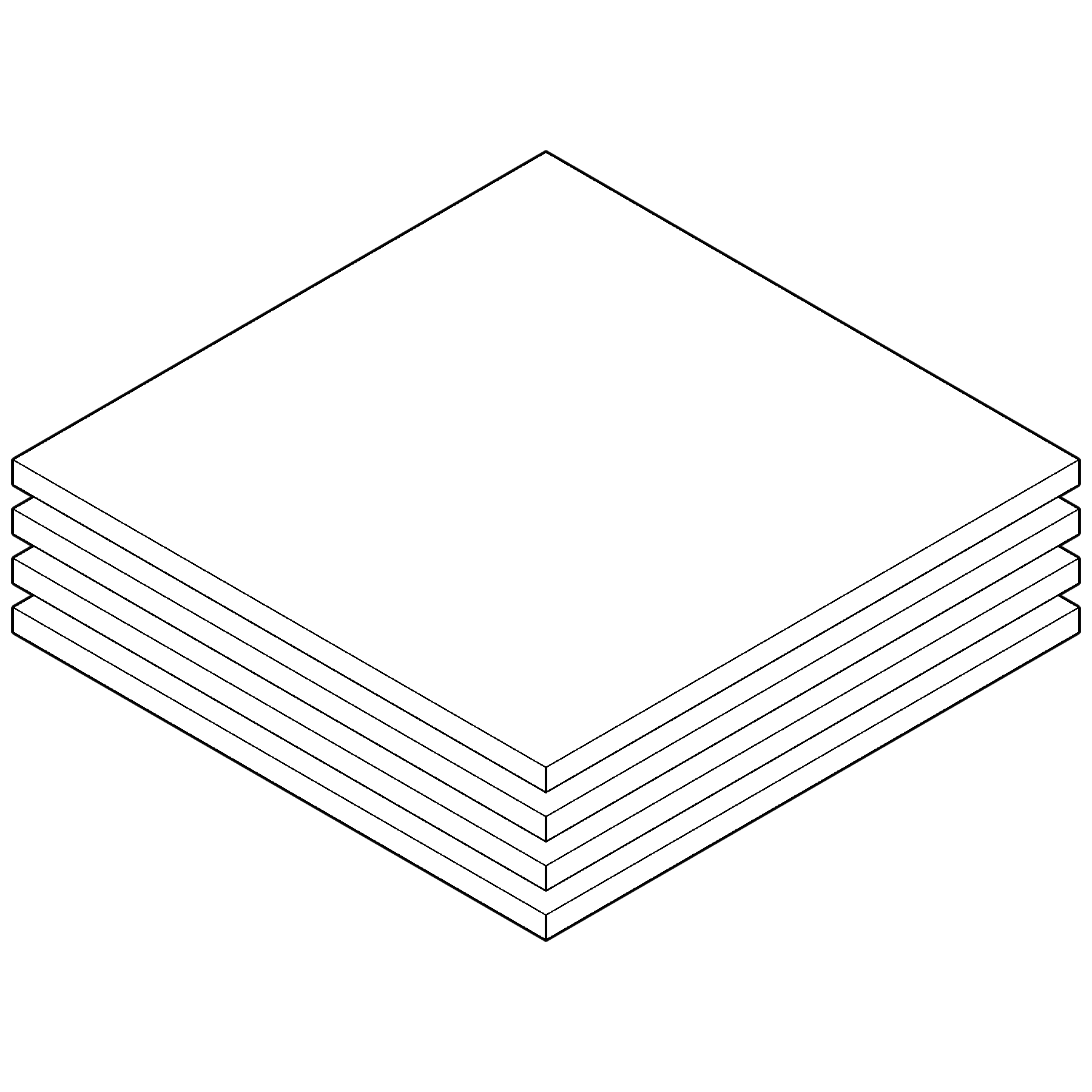

The paper honeycomb core is made using two different process Block and Continues methods, In Block Honeycomb, first Kraft paper reel is converted into paper sheets using paper sheet cutter, Kraft paper of 100 GSM to 150 GSM is used are per specification

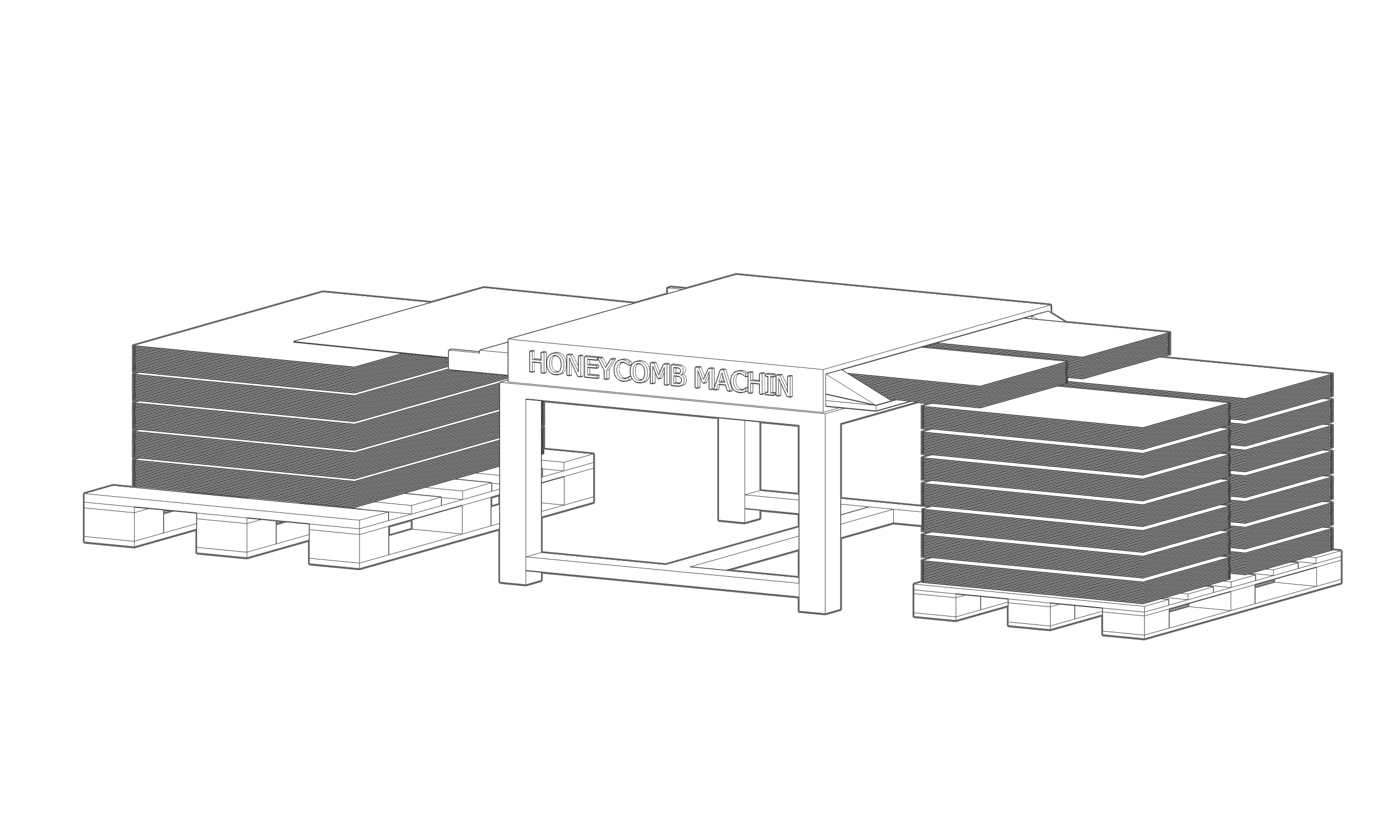

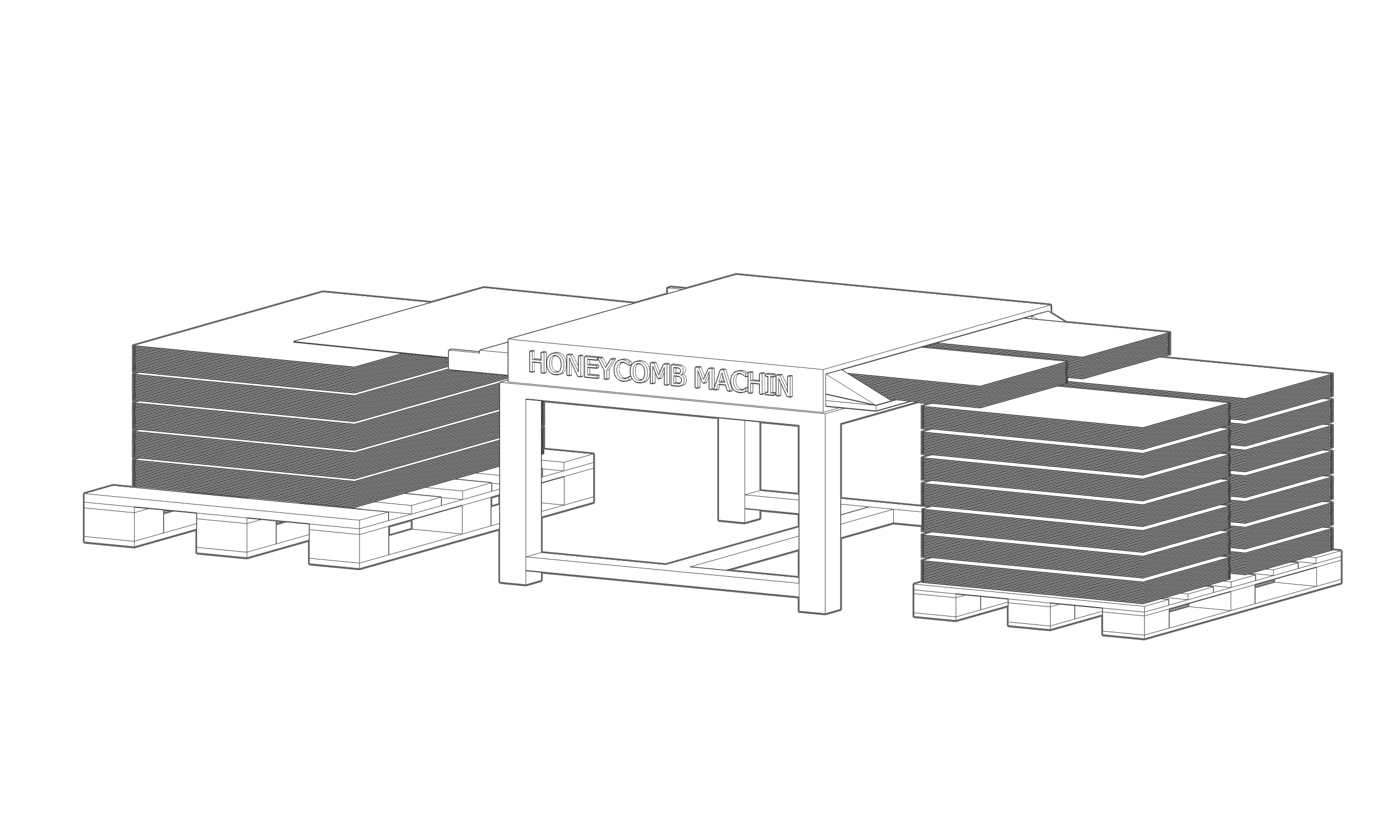

Paper sheets converted to Honeycomb Blocks

Paper sheets with help of water base glue converted to honeycomb blocks using paper honeycomb machine, these blocks are compress using cold press and keep for drying

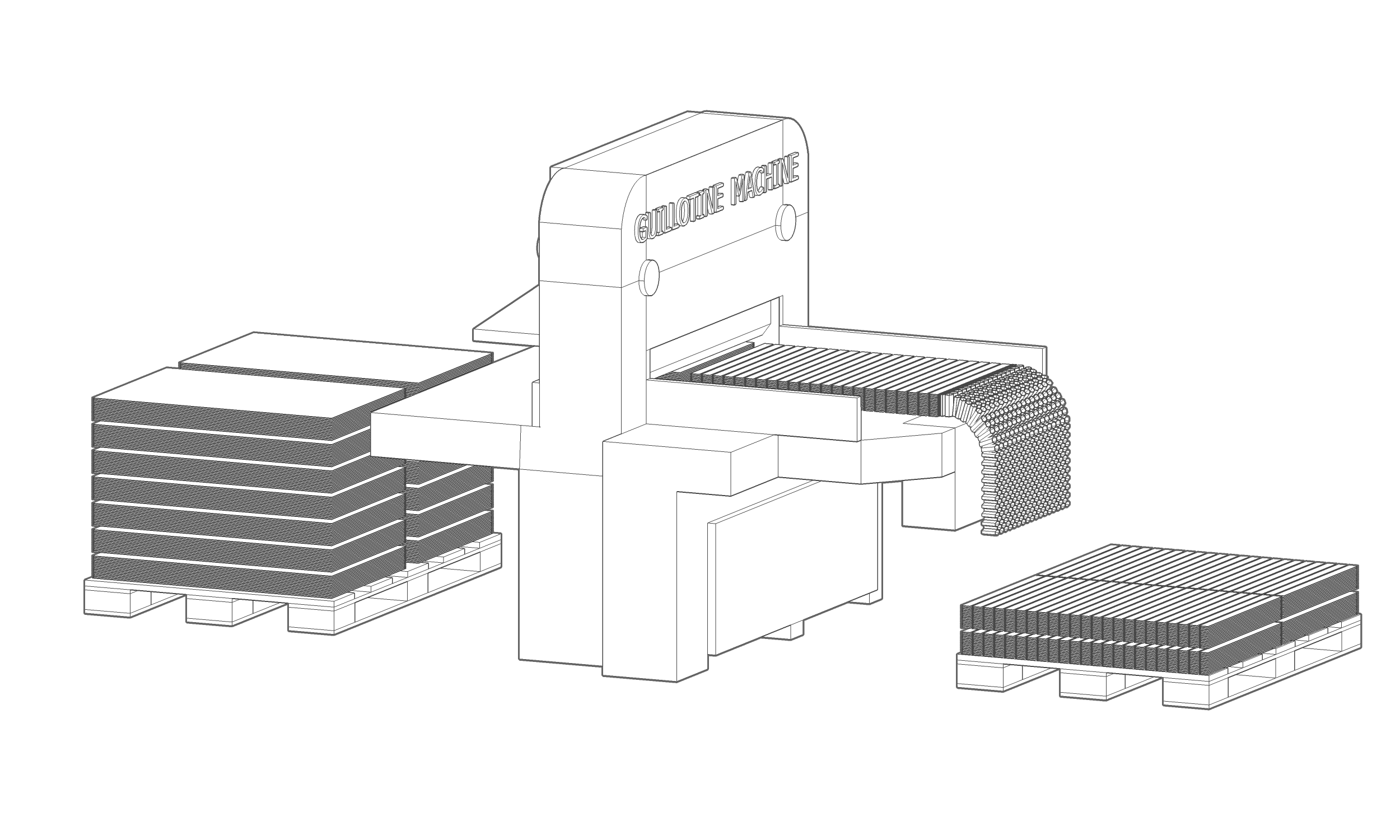

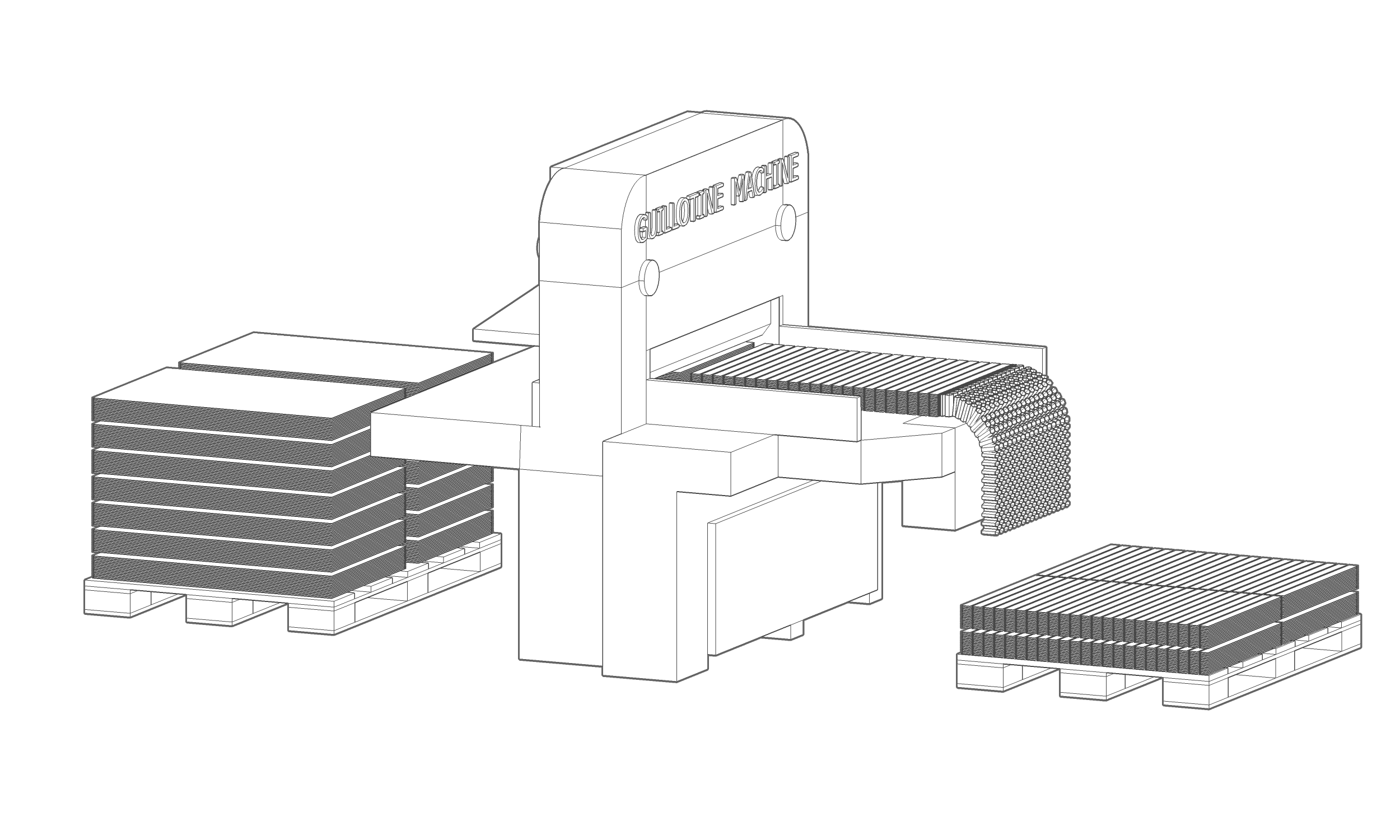

Honeycomb Blocks cut in size strips

Honeycomb block cut to the required size using Guillotine machine, Size of strip varies from 6mm to 100mm as per specifications. The strips glued to each other to create a continuous honeycomb core.

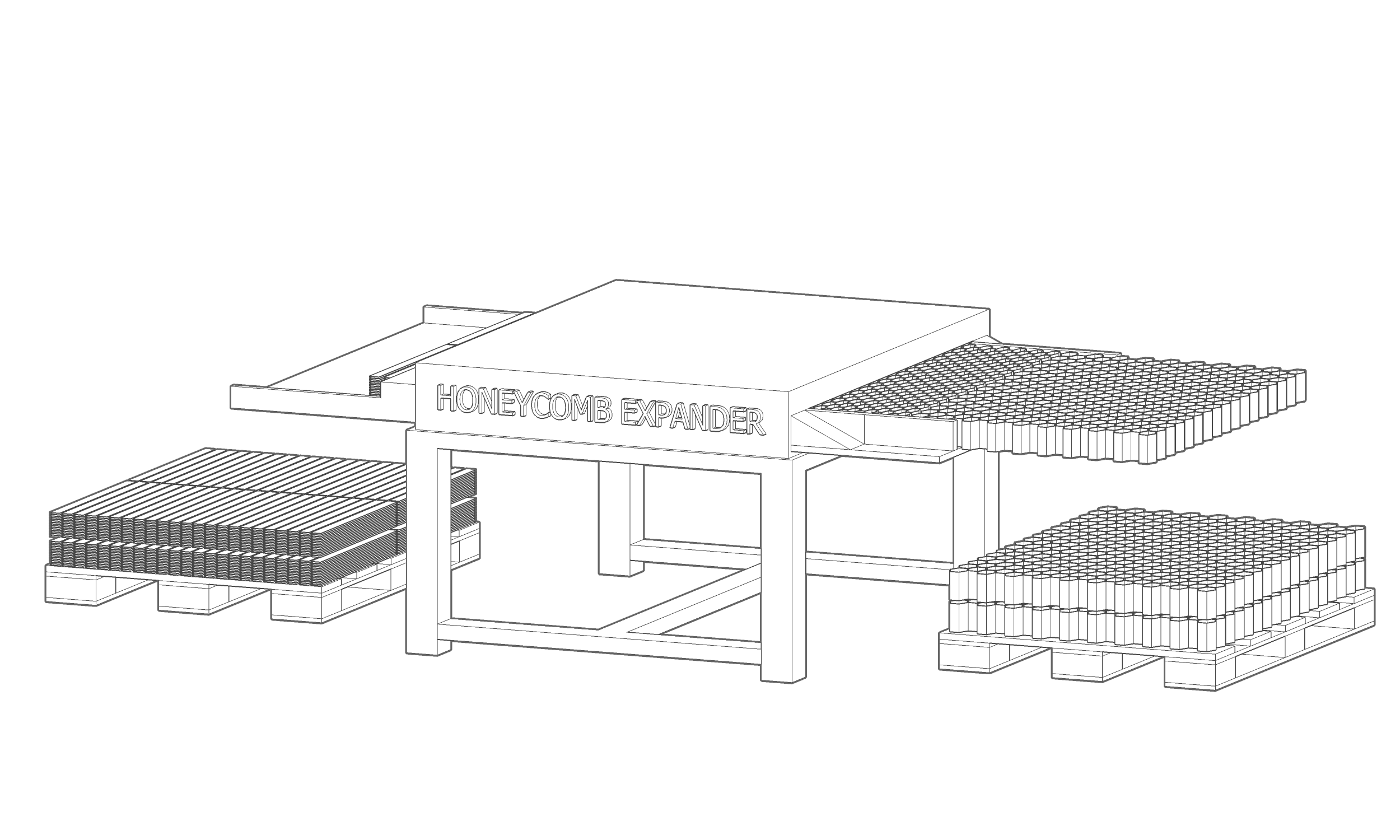

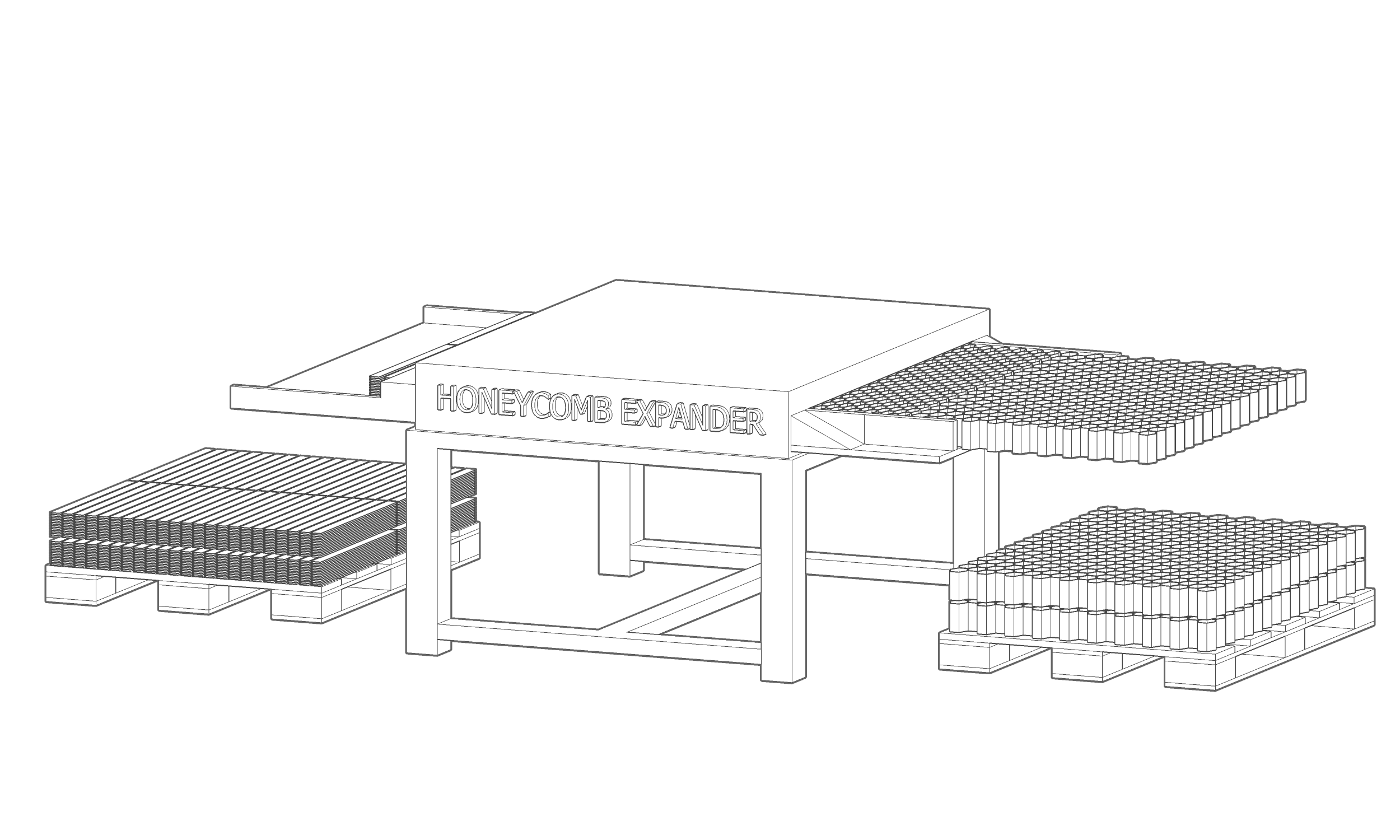

Strips are expanded to form Honeycomb Core

Honeycomb strips are expanded using the honeycomb expander machine, strip is expanded up to 75% in length to form the perfect hexagonal shape, its form expanded honeycomb core. Honeycomb core sandwich with face paper using PVA glue to form paper honeycomb panel, this panel is used in various applications

Features & Benefits

- Lightweight and Versatile

- High Strength-to-Weight Ratio

- High Stiffness-to-Weight Ratio

- Excellent Shock Absorption

- 100% Recyclable and Eco-friendly

- Energy Absorption and Damage Protection

- Clean and Contaminate Free

- Material Reduction

- Manufactured from Recycled Material

- Endless Range of Application Options

Application of Honeycomb

- Customized Packaging Solutions

- Honeycomb Core and Panels

- Void Fillers & Buffers

- Weight Spreaders & Spacers

- Impact & Edge Protectors

- Protective Wrap & Dividers

- Pallets & Pallet Box

- Exhibitions, Trade fairs

- Display & Construction Panels

- Honeycomb Doors & Furniture

- More Details on Product

Technical Data

Cell Data

Cell Size: 15mm, 20mm, 24mm, 27mm, 32mm

Compressive strength: 8 kg/cm2 to 1.5 kg/cm2

Paper: 100gsm to 150gsm

Thickness: 10mm to 100mm

Width: 800mm (Max Unexpended)

Length: 2500mm

* (Cell Size below 15mm as Special Order)

Surface Paper

Test liner: 100gsm to 300gsm

Kraft liner: 250gsm to 440gsm

Panel Details

Panel Thickness: 15mm to 50mm

Panel Width: 1200mm *

Maximum Length: 2500mm *

Compressive Strength: 1.5 kg/cm2 to 8 kg/cm2

* (Higher size on request)

Tolerances

Length/Width: +/- 0.5 mm

Height: +/- 0.5 mm